With over 30 years of experience, we specialize in providing NDT Services to a variety of aerospace, marine, and industrial clients. Non-destructive testing is used to assure maximum reliability of both metallic and non-metallic materials. The inspections we perform include; Liquid Penetrant, Magnetic Particle, Eddy Current, Ultrasonic/Phased Array, Radiography, Visual, and Thermography. It is imperative that personnel responsible for non-destructive testing be trained and highly qualified. At NDT-Solutions, we have the full support of an in-house ASNT Level III and all of our inspection personnel are qualified to the latest industry standards including NAS-410 and SNT-TC-1A.

Liquid Penetrant Testing or Inspection (LPI) is a method that is used to reveal open to surface discontinuities by bleedout of a colored or fluorescent dye. This technique is based on the ability of a liquid to be drawn into an open surface flaw by capillary action. After a period of time called “dwell” the excess penetrant is removed, and a developer is applied. This developer acts as a blotter and draws out penetrant from the flaw to reveal is presence. This test method can be used on an array of both nonporous metallic and nonmetallic materials.

Magnetic Particle Testing is a method that is used to test for surface and near-surface discontinuities in ferromagnetic materials. Magnetic Particle Testing uses magnetic fields and small magnetic particle to detect flaws in materials. The first step in magnetic particle testing is to magnetize the component that is to be inspected. If any defects on or near the surface are present, the defects will create a leakage field. After the component has been magnetized, colored or fluorescent dyed particle will be applied to the surface and reveal flaws visually.

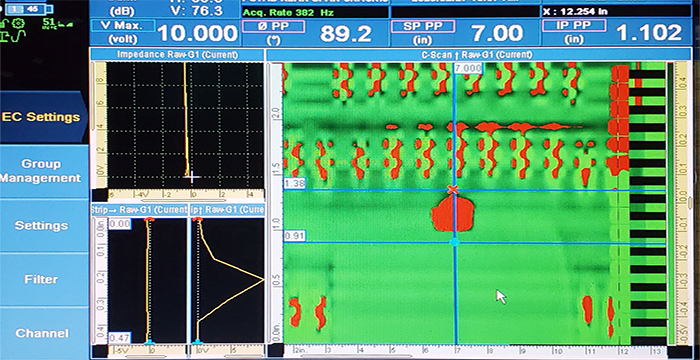

Eddy Current Testing is a method that uses the induction of eddy currents into an electrically conductive article and observing the resultant reaction between the magnetic fields involved. One of the major advantage of eddy current as an NDT tool is the variety of inspections and measurements that can be performed. Eddy currents can be used for:

Ultrasonic Testing (UT) uses high frequency sound energy to conduct examinations and make measurements. In the most common UT applications, very short pulse-waves are transmitted into materials using a transducer. When there is a discountinuity in the wave path, part of the energy will be reflected back from the flaw surface. This energy is then transformed into an electrical signal by the transducer and is displayed on a screen. Ultrasonic Testing cane be used for flaw detection/evaluation, dimensional measurements, material charactization, and more.

Phased Array Ultrasonic Testing (PAUT) is an advanced method of ultrasonic testing that uses many small transducers, each of which may be pulsed independently with computer calculated timing. PAUT is capable of creating detailed and accurate cross-section view of the part. Due to the ability to control more parameters such as beam angle and focal distance, PAUT is very efficient regarding the defect detection and speed of testing in comparison to conventional ultrasonic testing. PAUT can be used to inspect almost any material where traditional UT methods have been utilized.

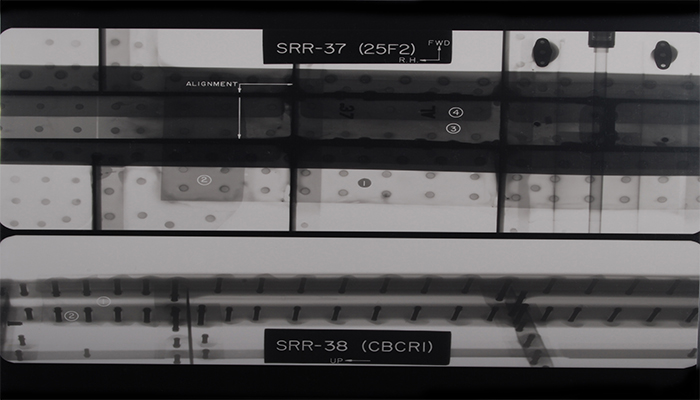

Radiography Testing is an imagining technique that using x-rays or ionizing radiation to create internal images of an object. Radiography Testing uses high energy electrons which collide with a metal target, usually made of an alloy of tungsten. When this high energy electron hits or passes near the nucleus of a tungsten atom, it makes a sudden deceleration and change in direction. This loss of kinetic energy is transferred into radiation energy in the forms of x-rays. This process is more commonly known as the Bremsstrahlung process. Some of this energy is absorbed by the material while some passes through. This energy is captured by a detector, usually a film to create an image. X-rays are a form of electromagnetic radiation, same in nature as light, but of much shorter wavelength. This high energy electromagnetic waves can pose serious health hazards if exposed. Here at NDT-Solutions, we have the benefit of an in-house Radiation Safety Office (RSO), to ensure that all of our radiography technicians meet the latest safety standard and are licensed IRRSP holders.

Thermography involves the testing of materials or systems through imaging of the thermal patterns of an objects surface. The basic theory of thermography is that the flow of heat from the surface of a solid is affected by internal flaws such as disbonds, voids, and inclusions. Excitation of the surface can be accomplished by an external energy input such as convection or use of a flash lamp (Pulse Thermography).